Introduction

Yuanda Biomass Fired Boiler

#BIOMASS_STEAM_BOILER #BIOMASS_HOT_WATER BOILER #BIOMASS_THERMAL_OIL_BOILER

Certified by ASME, CE, ISO, EAC, DOSH, TUV, BV, ensuring high quality and compliance with international standards.

Most Popular: DZL Automatic Biomass Boiler

1. Available to burn biomass, wood, sawdust, pellets, shells, ricehusk, coconuts, palm shells, palm fibre, solid waste.

2. Most popular DZL biomass boiler, kind of single drum & water-fire tubes biomass boiler, with automatic fuel feeding boiler. Combusition furnace with chain grate or reciprocating grate (DZW).

Biomass Boiler Features

1. DZ series automatic grate biomass boiler, we could adjust the hand lever and button to control the feeding/combustions condition, can operate easily efficiently.

2. DZ series biomass boiler, is famous with features "water-tube & fire-tube structure" "wing-shape flue" "unique boiler arch" "customized furnace according the biomass"

3. Make it environment-friendly, we will arrange devices such air-preheater/economizer/exhaust gas boiler, reuse the heat energy from high-temperature.

DZL DZW DZH DZG Biomass Boiler

1. DZL & DZW & DZH & DZG biomass boilers, big difference in combustion device. Using different grate stoker, such chain grate, reciprocating grate, travelling grate, fixed grate.

We will recommend the best suitable boiler according to The Specific Biomass Characteristics.

2. DZL & DZH biomass boiler, DZL is automatic type and DZH is manual type for biomass feeding way, boilers inner structure design are different. Refer to thermal efficiency, DZL boiler has higher thermal efficiency than DZH boiler.

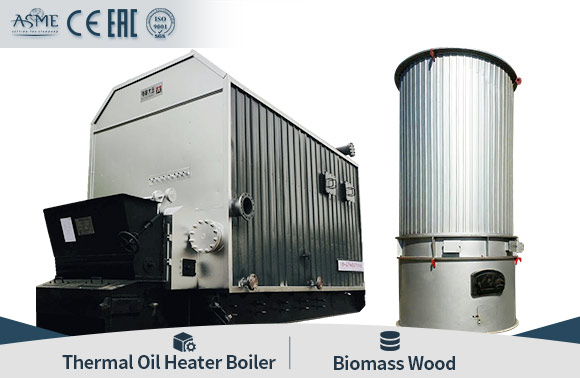

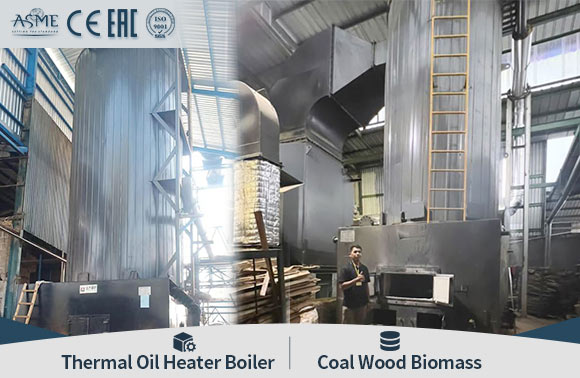

Related: Biomass Thermal Oil Boiler

Biomass hot oil boiler (biomass thermic fluid heater) (biomass thermal oil heater) 200kw-28000kw 300000kcal-12million kcal, in vertical or horizontal.

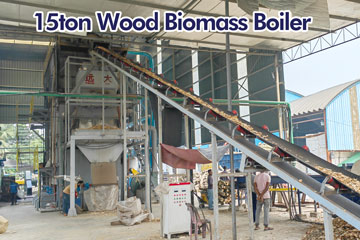

Related: Biomass Water Tube Boiler

SZL water tube biomass boiler, chain grate or reciprocating grate boiler 4ton-50tons, double drums & water membrane walls & higher efficiency & superior design. Popular demand in 10/15/20/25/30tons.

Related: Small Biomass Boiler

Small Biomass Pellets Boiler | Small Woodchips Boiler | Vertical Wood Biomass Boiler.

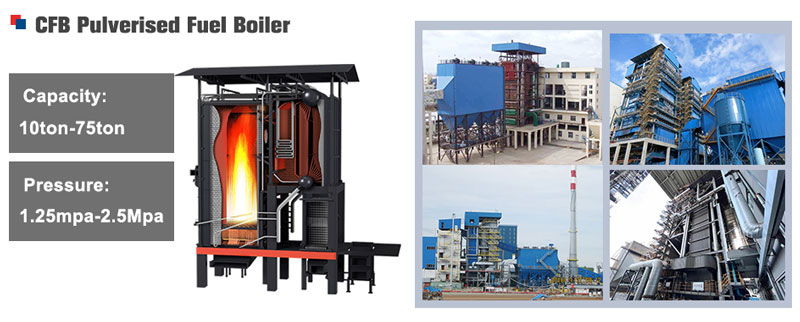

Related: Pulverised Fuel Boiler

10ton-75ton CFB pulverised fuel boiler, Burning Woodwaste, Ricehusk, Straw, Bagasse, Corn cobs, Energy crops, Industrial residues.

Technical Parameter

| DZ Series Steam Boiler Technical Parameter Table | |||||||||

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Boiler water volume(m³) | Exhaust temperation(℃) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| DZH1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 127.25 | 192.32 | 9 |

| DZL1 | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 3.15 | 113.34 | 190.42 | 13.5 |

| DZH2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.75 | 126.41 | 386.47 | 15 |

| DZL2 | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 4.77 | 106.34 | 393.77 | 22 |

| DZH4 | 4 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | >82 | 7.7 | 137.25 | 782.29 | 18.5 |

| DZL4 | 4 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.2 | 124.49 | 756.89 | 27.6 |

| DZH6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 7.4 | 146.83 | 1169.57 | 25 |

| DZL6 | 6 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 8.1 | 137.29 | 1148.68 | 35 |

| DZL8 | 8 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | >82 | 9.6 | 141.06 | 1602.44 | 38 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Our Supply Equipment List

Boiler Features

Chain grate/Reciprocating grate

Auto-feeding type burning system, avoid problem of air leakage, fuel leakage and uneven ventilation. Easier operation compared to traditional grate.

Fire tubes & Wing shape structure

Strengthening heat transfer, eliminating welding stress, enhance heat transfer bility, reduce heat stress of pipeline seam, prevent pipeline cracking.

Security guaranteed & Automation

With a set of alarm,protection and security guaranteed, 100% safety. Control cabinet use siemens elements, trustable quality & control strictly

Economizer & Dust collector device

Reuse waste heat in exhaust gas, energy saving devide (economizer); Remove the dust and ash, protect envrionment and reduce pollutionBoiler Advantages

Higher efficiency & Energy-saving

Optimized design CAD furnace/coil pipe sturcture/new arch design, enhancing heat transfer efficiency. Equipped with energy saving device such as economizer to absorb heat of exhaust gas, economic & eco-friendly.

Automatic feeding coal/biomass boiler

Automatic chain belt grate, easier operation, avoid the problem of air leakage/fuel leakage/uneven ventilation. Double-sided air inlet chamber can flexibly adjust the air volume and distribute the air uniformly to ensure full combustion.

High Quality & Strong Power

Design steam-water separator, reduce steam humidity and ensure steam quality. Boiler design 5-10% overload capacity, satisfy customers' demand for factory using. Enough steam output per hour.

Safety & 25+Years Lifespan

We already manufacturing boiler for 60+Years, mature skilled technician team, advanced production processes, strict quality inspection control, CE & ISO certified quality, global service for boiler install & commissioning & training operator.

PRODUCTS LIST

More Products

Contact Supplier

Send Inquiry

Product capacity:

Product capacity: Working pressure:

Working pressure: Available fuel:

Available fuel: Available industries:

Available industries: