Introduction

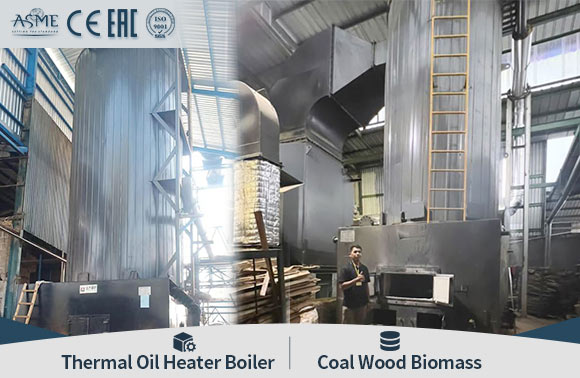

Biomass Burner Boiler | Fire Tube Biomass Boiler

1. Wood/Biomass fire tube boiler, consist of two parts (biomass burner & fire tube boiler).

2. Specially, the new model biomass burner boiler could be converted as gas/diesel oil burner boiler easily. (showing in picture as follows)

2. Biomass burner is a type of biomass semi-gasification automatic control type burner, which uses wood chips, wood powder, sawdust and other organic biomass as fuel. Work automatically and higher combustion efficiency.

1. Boiler Working Principle

It use biomass burner device burning biomass supplying heating source, then high-temperature flue gas into fire tube boiler, three pass structure for heating water, help improve thermal efficiency.

2. Available fuel

biomass pellets, wood pellets, wood chips, wood flour, sawdust, rice husk, peanut husk, straw, palm flour, etc

3. Biomass Burner Introduction

Biomass semi-gasification automatic control type burner, through the automatic feeding device, the biomass particles are sent into the combustion chamber for direct combustion, and the burned heat can be directly used in boilers, spraying, die-casting, clothing, hotels, heat treatment and other heating equipment.

4. Biomass Burner Boiler System

5. Advantages of Biomass Burner Boiler

1. High-efficiency and energy-saving: Renewable biomass pellet fuel is used as energy source, the using cost is low, and the operating cost is 30%-60% lower than that of fuel oil/gas.

2. High thermal efficiency: semi-gasified suspension combustion with tangent a swirl flow air distribution design, low temperature staged combustion, burnout rate of more than 98%, and furnace temperature of more than 1200 ℃.

3. Stable and reliable: Micro-positive pressure operation, silo isolation transportation method, no tempering and de-firing phenomenon, has applied for national invention patent.

4. Low-carbon environmental protection: low smoke, sulfur and nitrogen emissions, and nearly zero carbon dioxide emissions, accord with smoke emission requirements.

5. Simple operation: easy installation, automatic feeding, simple operation, less workload, large silo capacity (larger capacity silo can be customized). The feeding can be run for 3-12 hours at a time, only need to fill the bin in time, only one person on duty is OK.

> How to Choose A Suitable Boiler

1. Basic Boiler Information For Your Project

Fuel options: Gas Lpg Diesel Heavy-oil Biogas Dual-fuel, Electricity, Coal, Charcoal, Wood, Biomass, Pellets, EFB Palm-kernel-shells, Rice-husk, Peanut-shells, Cashew-nuts-shells, Sunflower-seeds-shells, Bagasse, etc.

Thermal capacities options: 100kg-50000kg, 70kw-35000kw, 5hp/bhp-3000hp/bhp, (million-btu, pounds/lbs, liters,etc)

Heat medium options: saturated/superheated steam, hot water, thermal oil.

Structure options: Fire tube boiler, water tube boiler, water-tube fire-tube boiler

Layout options: Vertical boiler, Horizontal boiler.

Operating-mode options: Automatic, manual

Note: please feel free to send all requirements, we could help you better.

2. Calculating Running Cost

Specific consumption analysis report

Different types boiler running consumption comparison analysis report

(Note: Report is based on your local energy source price)

3. Boiler Accessories (essential or optional)

Control panel, Water treatment device, Economizer, Conderser, Heat recovery unit, Deaerator, Solid fuel burning combustions stoker (chain-grate, reciprocating-grate, travelling-grate, fixed-grate), Steam header, Pumps, Water level gauge/sensor, Pressure guage/sensor, Safety valves, etc.

Note: Any special request, please send all details.

Technical Parameter

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated temperature(℃) | feed temperature(℃) | Exhaust temperation(℃) | max transportation weigh(t) |

| WNS0.5-1.0/1.25/1.6-YQ | 0.5 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | 60-75 | 3.5 |

| WNS1-1.0/1.25/1.6-YQ | 1 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | 60-75 | 5.5 |

| WNS2-1.0/1.25/1.6-YQ | 2 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | 60-75 | 8 |

| WNS3-1.0/1.25/1.6-YQ | 3 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | 60-75 | 10.7 |

| WNS4-1.0/1.25/1.6-YQ | 4 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | 60-75 | 11.6 |

| WNS6-1.0/1.25/1.6-YQ | 6 | 1.0/1.25/1.6 | 184/194/204 | 20/104 | 60-75 | 17.5 |

| WNS8-1.0/1.25/1.6/2.5-YQ | 8 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | 60-75 | 22.5 |

| WNS10-1.0/1.25/1.6/2.5-YQ | 10 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | 60-75 | 26.8 |

| WNS15-1.0/1.25/1.6/2.5-YQ | 15 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | 60-75 | 35.2 |

| WNS20-1.0/1.25/1.6/2.5-YQ | 20 | 1.0/1.25/1.6/2.5 | 184/194/204/226 | 20/104 | 60-75 | 45.5 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | ||||||

Our Supply Equipment List

Boiler Features

Biomass Fire Tube Furnace Structure

Horizontal three pass fire tube boiler, corrugated furnace & sparilly corrugated tubes, improve heat transfer, higher thermal efficiency.

Biomass Burner

Biomass burner is type of biomass semi-gasification automatic control type burner, could be used for burning husk, shells, peanuts, palm fibre, chips, etc.

Water Treatment Device

Hard water is softened by removing the hardness minerals in the water through a process called ion exchange.

Economizer & Dust collector device

Reuse waste heat in exhaust gas, energy saving devide (economizer); Remove the dust and ash, protect envrionment and reduce pollution.PRODUCTS LIST

More Products

Contact Supplier

Send Inquiry

Product capacity:

Product capacity: Working pressure:

Working pressure: Available fuel:

Available fuel: Available industries:

Available industries: