Introduction

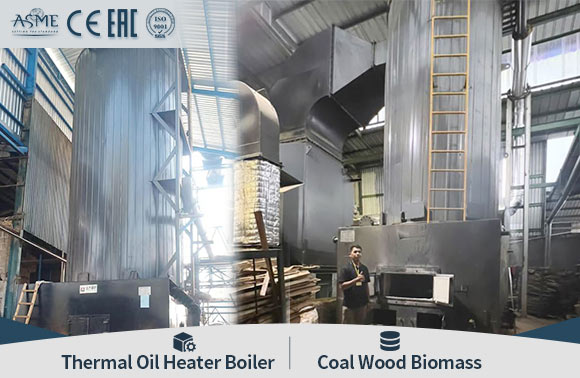

Circulating Fluid Bed Coal Boiler

#STEAM_BOILER #HOT_WATER_BOILER

Certified by ASME, CE, ISO, EAC, DOSH, TUV, BV, ensuring high quality and compliance with international standards.

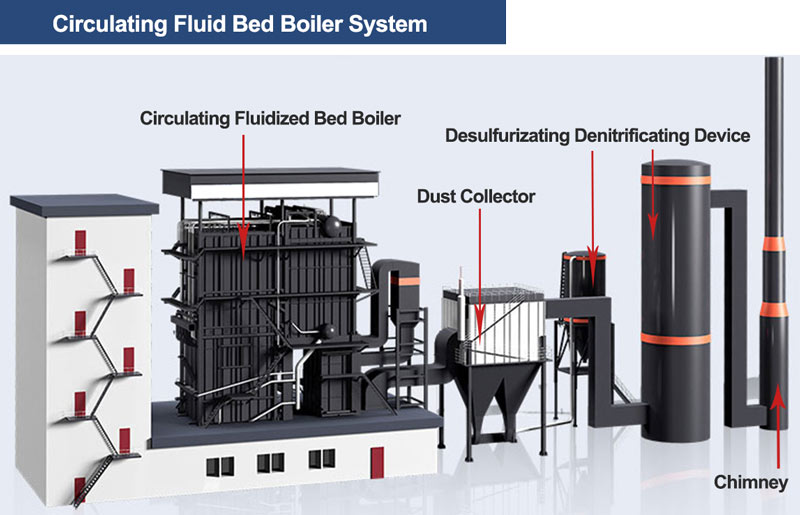

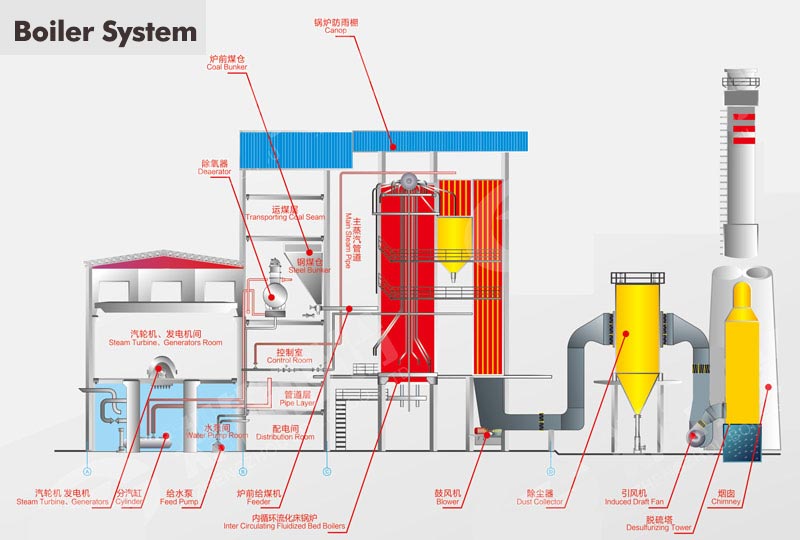

Circulating fluidized bed combustion technology, is kind of new and mature coal combustion clean technology, with high-efficiency, low-pollution.

According to the structural form, it can also be divided into the following models:

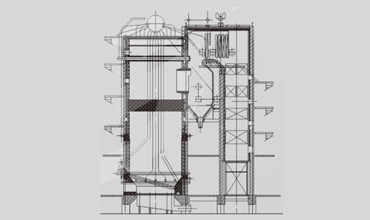

1. SHX series circulating fluidized bed boiler (double drum horizontal type)

2. DHX series circulating fluidized bed boiler (single drum horizontal type)

3. QXX external circulating fluidized bed hot water boiler (forced circulation type, divided into high-speed and low-speed circulating fluidized bed boilers)

4. Circulating fluidized bed power station boiler

Advantages of CFB Boiler

1. Low coal consumption: high-efficiency separation + circulating combustion, combustion efficiency >99% or more, thermal efficiency >92%, coal consumption reduced by more than 3%

2. Save electricity bills: Restructure the flow pattern to achieve low bed pressure operation. The low power consumption rate of the factory can save more than 20% of the fan power consumption.

3. Environmental protection and low emissions: precise low-temperature staged combustion and air distribution, ultra-low initial emissions of SO2 and NOx, and superior environmental performance

4. Low wear: low bed pressure operation, low flue gas flow rate, nearly zero wear on the heating surface, low maintenance rate, annual operating time >8000 hours

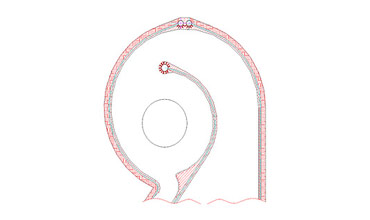

5. Good fluidization: Patented improved bell-type wind cap solves the problems of ash pouring and fluidization to ensure boiler combustion efficiency and low emissions

6. High separation: The optimized center-offset high-efficiency cyclone separator is used to ensure efficient separation, with an efficiency of over 99.6

Technical Parameter

| SHX Series Circulating Fluidized Bed Steam Boiler Parameters | |||||

| Model | Capacity (ton/h) | Working Pressure | Steam Temperature | Input Water Temp. | Factory mode |

| SHX10 | 10 | 1.25Mpa-3.82Mpa | 194℃-450℃ | 105℃-112℃ | Field Assembly |

| SHX15 | 15 | ||||

| SHX20 | 20 | ||||

| SHX25 | 25 | ||||

| SHX30 | 30 | ||||

| SHX35 | 35 | ||||

| SHX40 | 40 | ||||

| SHX45 | 45 | ||||

| SHX50 | 50 | ||||

| SHX55 | 55 | ||||

| SHX60 | 60 | ||||

| SHX65 | 65 | ||||

| SHX70 | 70 | ||||

| SHX75 | 75 | ||||

Auxiliary System

Features of CFB Boiler

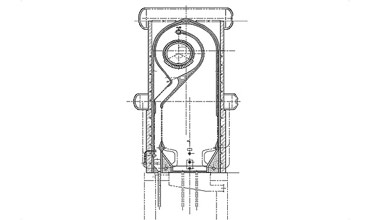

Unique separator design

The combustor, separator and fly ash returning system is united as a whole by membrane water cooling wall, the overall boiler structure is compact and stable.

Unique separator design

The membrane wall can absorb heat of the lining, allowing residual carbon in the flue gas to continue burning in the separator, will not cause coking and enhance the separation efficiency.

Wear-resisting design

Pipe using welding wear bars with the special angle and size to prevent wear on the tubular pipe.

Fuel adaptability and lower cost

It can burn anthracite, lean coal, bituminous coal, coal gangue, chain slag, and other low-grade fuel that other burning furnace can not burn.Contact Supplier

Product capacity:

Product capacity: Working pressure:

Working pressure: Available fuel:

Available fuel: Available industries:

Available industries: