Introduction

SZL Water Tube Coal boiler

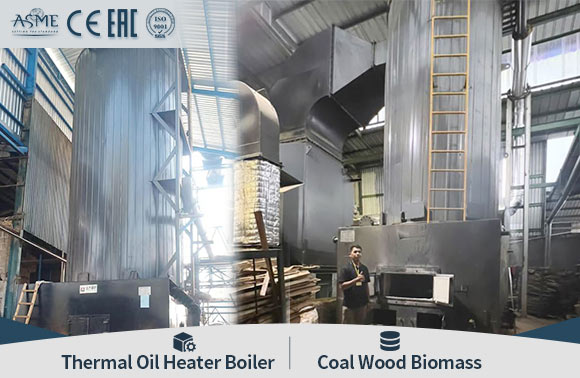

Certified by ASME, CE, ISO, EAC, DOSH, TUV, BV, ensuring high quality and compliance with international standards.

SZL water tube coal fired boiler, suitable for capacity demand in 2ton-50ton. It is double-drums water tube assembly chain grate boiler (A/D type). High technology, environmental and energy-saving. Large heating surface, make sure enough space for biomass burning, automatic fuel feeding and slag removing system.

Core Technology of SZL Boiler:

1. Cyclone chamber structure, high-temp flue gas through high-speed rotation/mixing combustion/dust separation, achieving dust removal & energy saving & environmental protection.

2. Indenpend wind chamber structure, make air regulation sensitive and make wind uniformly, resolve the wind plug, wind channeled, partial burn phenomenon.

3. Membrane water wall construction, structure advantages of high heat transfer coefficient, good heat transfer effect, low heat loss, good air tightness of furnace wall.

> How to Choose A Suitable Boiler

1. Basic Boiler Information For Your Project

Fuel options: Gas Lpg Diesel Heavy-oil Biogas Dual-fuel, Electricity, Coal, Charcoal, Wood, Biomass, Pellets, EFB Palm-kernel-shells, Rice-husk, Peanut-shells, Cashew-nuts-shells, Sunflower-seeds-shells, Bagasse, etc.

Thermal capacities options: 100kg-50000kg, 70kw-35000kw, 5hp/bhp-3000hp/bhp, (million-btu, pounds/lbs, liters,etc)

Heat medium options: saturated/superheated steam, hot water, thermal oil.

Structure options: Fire tube boiler, water tube boiler, water-tube fire-tube boiler

Layout options: Vertical boiler, Horizontal boiler.

Operating-mode options: Automatic, manual

Note: please feel free to send all requirements, we could help you better.

2. Calculating Running Cost

Specific consumption analysis report

Different types boiler running consumption comparison analysis report

(Note: Report is based on your local energy source price)

3. Boiler Accessories (essential or optional)

Control panel, Water treatment device, Economizer, Conderser, Heat recovery unit, Deaerator, Solid fuel burning combustions stoker (chain-grate, reciprocating-grate, travelling-grate, fixed-grate), Steam header, Pumps, Water level gauge/sensor, Pressure guage/sensor, Safety valves, etc.

Note: Any special request, please send all details.

Technical Parameter

| SZL Series Steam Boiler Technical Parameter Table | |||||||||

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Boiler water volume(m³) | Exhaust temperation(℃) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| SZL2 | 2 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >83.13 | 6.76 | 130.7 | 385.8 | 22 |

| SZL4 | 4 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.23 | 5.1 | 142 | 807 | 29 |

| SZL6 | 6 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.81 | 8.4 | 142 | 1209 | 34 |

| SZL8 | 8 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >85.02 | 9.4 | 149.1 | 1563.9 | 40.5 |

| SZL10 | 10 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.2 | 8.35 | 152.7 | 2149.3 | 24 |

| SZL12 | 12 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.56 | 12.8 | 148.7 | 2399.7 | 37 |

| SZL15 | 15 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.29 | 15.2 | 149.8 | 2568.4 | 24.7 |

| SZL20 | 20 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.8 | 15.5 | 147.4 | 4266.9 | 26 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Our Supply Equipment List

SZL Boiler Advantages

Unique warehouse and auto feeding

The big speed bin design could control fuel transmit mass automatically according to the thermal energy, isolate flame and flue to prevent tempering

Whole membrane water wall

Increased 50% heating area than traditional, refractory brick furnace wall will reduce weight and transport cost, improve efficiency and energy saving

Security guaranteed & Automation

With a set of alarm,protection and security guaranteed, 100% safety. Control cabinet use siemens elements, trustable quality & control strictly

Economizer & Dust collector device

Reuse waste heat in exhaust gas, energy saving devide (economizer); Remove the dust and ash, protect envrionment and reduce pollutionProduct Features

Double drums new furnace design

Optimized design CAD furnace/corrugated tubes/wing shape flue/new arch design, enhancing heat transfer efficiency. Equipped with energy saving device such as economizer to absorb heat of exhaust gas, economic & eco-friendly.

Auto grate stoker water tube boiler

Automatic chain belt grate, easier operation, avoid the problem of air leakage/fuel leakage/uneven ventilation. Double-sided air inlet chamber can flexibly adjust the air volume and distribute the air uniformly to ensure full combustion.

High quality steam output by separator

Design steam-water separator, reduce steam humidity and ensure steam quality. Boiler design 5-10% overload capacity, satisfy customers' demand for factory using. Enough steam output per hour.

Quality certified boiler manufacturer

We already manufacturing boiler for 60+Years, mature skilled technician team, advanced production processes, strict quality inspection control, CE & ISO certified quality, global service for boiler install & commissioning & training operator.

PRODUCTS LIST

More Products

Contact Supplier

Send Inquiry

Product capacity:

Product capacity: Working pressure:

Working pressure: Available fuel:

Available fuel: Available industries:

Available industries: