Introduction

Biomass Palm Kernel Shell Boiler

Certified by ASME, CE, ISO, EAC, DOSH, TUV, BUV, ensuring high quality and compliance with international standards.

Biomass Boiler System Features:

Boilers designed for palm kernel shells focus on maximizing combustion efficiency, minimizing environmental impact, and ensuring reliable and safe operation. These features contribute to the utilization of PKS as a sustainable and efficient renewable energy source.

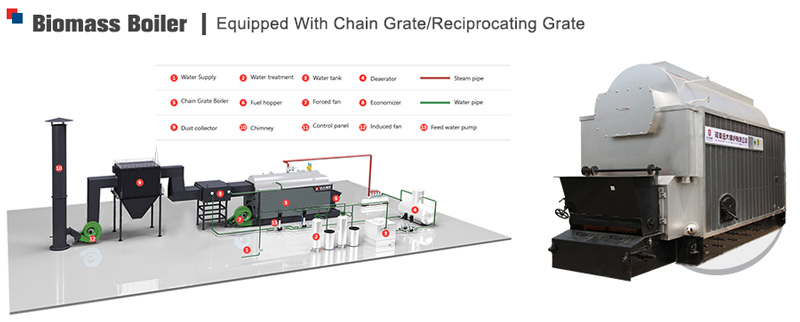

1. Grate Firing System: Specially designed grate firing system for palm kernel shells burning. This system allows for efficient combustion of palm kernel shells by ensuring proper airflow and controlled fuel distribution on the grate.

2. High Combustion Efficiency: Optimized combustion chamber design and ensuring proper mixing of air and fuel for complete and clean burning.

3. Ash Removal Mechanism: Boiler system helps in the efficient removal and disposal of the ash, preventing the build-up that could affect boiler performance.

4. Heat Recovery System: Using economizer to capture and utilize the waste heat generated during combustion, improving overall efficiency and reducing fuel consumption.

5. Compatibility with Biomass Fuels: Boiler can efficiently burn not only palm kernel shells but also other biomass materials.

6. Environmental Considerations: Equipped with emission control technologies to minimize environmental impact. Reducing particulate matter, nitrogen oxides, and other emissions produced during combustion.

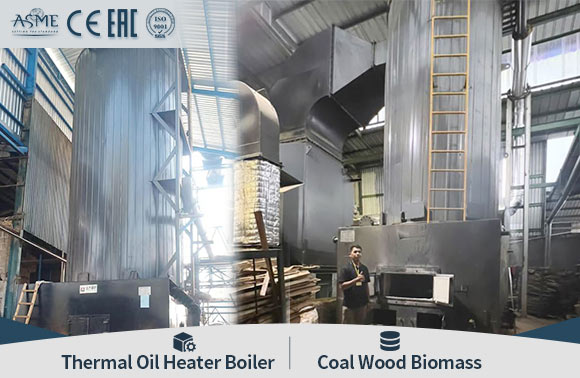

Solution A: DZL Biomass Boiler

DZL series palm kernel shells boiler 1ton 2ton 4ton 6ton 8ton.

Features: Automatic feeding with chain grate stoker, inner single drum & watertube firetube design.

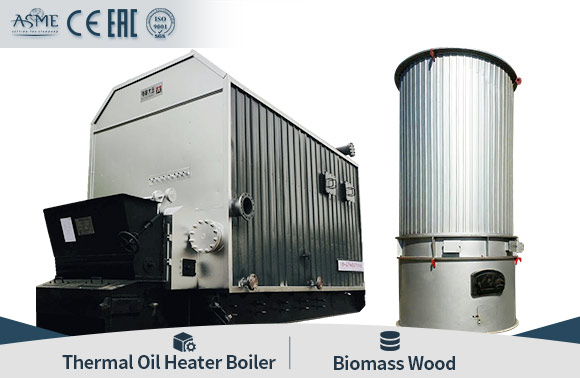

Solution B: SZL Series Water Tube Boiler

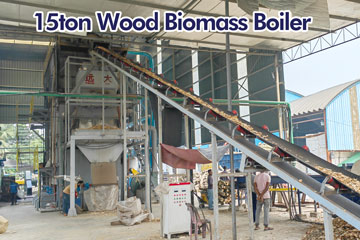

SZL water tube biomass boiler 2ton 4ton 6ton 8ton 10ton 12ton 15ton 20ton 30ton.

Features: Double water drums & Membrane water wall construction & cyclone chamber structure, special design help improving thermal efficiency.

> How to Choose A Suitable Boiler

1. Basic Boiler Information For Your Project

Fuel options: Gas Lpg Diesel Heavy-oil Biogas Dual-fuel, Electricity, Coal, Charcoal, Wood, Biomass, Pellets, EFB Palm-kernel-shells, Rice-husk, Peanut-shells, Cashew-nuts-shells, Sunflower-seeds-shells, Bagasse, etc.

Thermal capacities options: 100kg-50000kg, 70kw-35000kw, 5hp/bhp-3000hp/bhp, (million-btu, pounds/lbs, liters,etc)

Heat medium options: saturated/superheated steam, hot water, thermal oil.

Structure options: Fire tube boiler, water tube boiler, water-tube fire-tube boiler

Layout options: Vertical boiler, Horizontal boiler.

Operating-mode options: Automatic, manual

Note: please feel free to send all requirements, we could help you better.

2. Calculating Running Cost

Specific consumption analysis report

Different types boiler running consumption comparison analysis report

(Note: Report is based on your local energy source price)

3. Boiler Accessories (essential or optional)

Control panel, Water treatment device, Economizer, Conderser, Heat recovery unit, Deaerator, Solid fuel burning combustions stoker (chain-grate, reciprocating-grate, travelling-grate, fixed-grate), Steam header, Pumps, Water level gauge/sensor, Pressure guage/sensor, Safety valves, etc.

Note: Any special request, please send all details.

Technical Parameter

| SZL Series Biomass Boiler Technical Parameter Table | |||||||||

| Model | Rated capacity(t/h) | Rated pressure (Mpa) | Rated steam temperature(℃) | feed temperature(℃) | Thermal efficiency(%) | Boiler water volume(m³) | Exhaust temperation(℃) | Fuel comsumption(Kg/h) | max transportation weigh(t) |

| SZL2 | 2 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >83.13 | 6.76 | 130.7 | 385.8 | 22 |

| SZL4 | 4 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.23 | 5.1 | 142 | 807 | 29 |

| SZL6 | 6 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >84.81 | 8.4 | 142 | 1209 | 34 |

| SZL8 | 8 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >85.02 | 9.4 | 149.1 | 1563.9 | 40.5 |

| SZL10 | 10 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.2 | 8.35 | 152.7 | 2149.3 | 24 |

| SZL12 | 12 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.56 | 12.8 | 148.7 | 2399.7 | 37 |

| SZL15 | 15 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.29 | 15.2 | 149.8 | 2568.4 | 24.7 |

| SZL20 | 20 | 1.25/1.6/2.5/3.82 | 194/204/226/450 | 20/104 | >86.8 | 15.5 | 147.4 | 4266.9 | 26 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||||

Our Supply Equipment List

SZL Boiler Advantages

Auto feeding & Unique warehouse

Use automatic feeding chain grate stoker. Big speed bin could control fuel transmit mass automatically, isolate flame and flue to prevent tempering

Whole membrane water wall

Increased 50% heating area than traditional, refractory brick furnace wall will reduce weight and transport cost, improve efficiency and energy saving

Control and Monitoring Systems

Equipped with sophisticated control and monitoring systems to regulate combustion parameters & monitor boiler,ensure safe and optimal operation.

Economizer & Dust collector device

Reuse waste heat in exhaust gas, higher thermal efficiency; Reducing particulate matter, nitrogen oxides, and other emissions.FAQ of Palm Shells Boiler

Question: what's the efficiency of SZL biomass boiler?

Answer: Our SZL biomass boiler has higher efficiency than other old design boiler, take 10ton palm shells boiler example, thermal efficiency > 86.2%

Question: Do you have other models of biomass boiler?

Answer: Yes, we have kinds of biomass boilers, it could be devided to chain grate biomass boiler, travelling grate biomass boiler, reciprocating grate biomass boiler...

Question: Do you support customized boiler service for projects?

Answer: Yes, we have technique research center team, make unique boiler solution. Our company established since1956, the boilers have covered 90countries.

PRODUCTS LIST

More Products

Contact Supplier

Send Inquiry

Product capacity:

Product capacity: Working pressure:

Working pressure: Available fuel:

Available fuel: Available industries:

Available industries: