Introduction

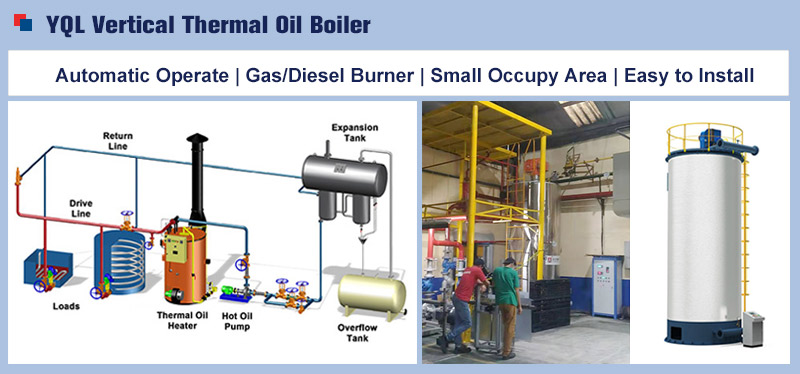

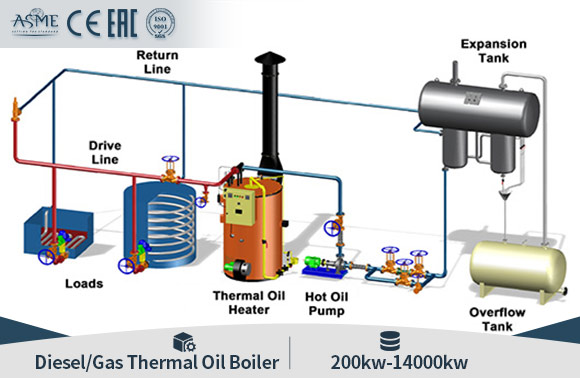

Vertical Thermal Oil Boiler

Powered by gas, lpg, diesel oil, Automatic thermal oil boiler with burner (brand of baltur, riello, unigas, ecoflame, oilon, etc.)

Structure:YY(Q)L series thermal oil boiler, it's vertical chamber-fired three-coil structure, and the body is composed of an outer coil, a middle coil and an inner coil. Compared to horizontal one, this vertical oil heater boiler has a smaller occupy area.

Whole System including oil heater boiler proper, burner, control cabinet, oil expansion tank, oil storage tank, oil circulating pumps, economizer, chimney, pipes, valves, gauges, etc.

Advantages of YQL thermal oil boiler

Energy efficient

1. Close packed disc tube heating surface, heating surface layout adequacy, multi-backhaul heat exchanger.

2. Furnace size match with burning flame, radiation heat transfer efficiency.

3. Positive pressure combustin, so that combustion efficiency is greatly improved.

4. Boiler quality insulation materials and special construction technology, less heat loss, ther exhaust gas temperature is low, the high thermal efficiency of ther boiler.

5. By fully rational surface layout, boiler warming fast start.

Safe and reliable

1. Close-packed disc tube heating surface heating surface arrangement sufficient to reduce the tube sheet heat load, conducting oil safer to use.

2. The boiler operation monitor remote and nearly complete automatic control and monitoring instrumentation, safe, reliable, easy to operate

Easy to install

Boiler full assembled, compact structure, small footprint, is extremely easy to install and flexible, as long as the boiler is located based on.

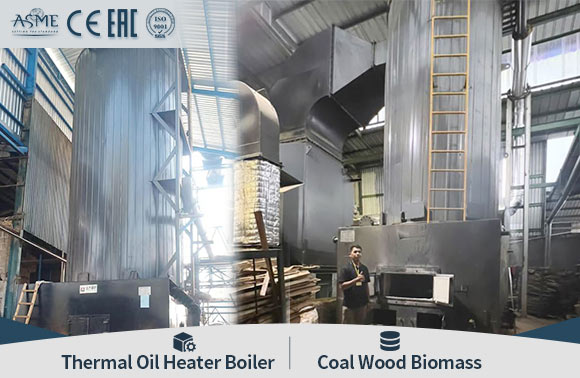

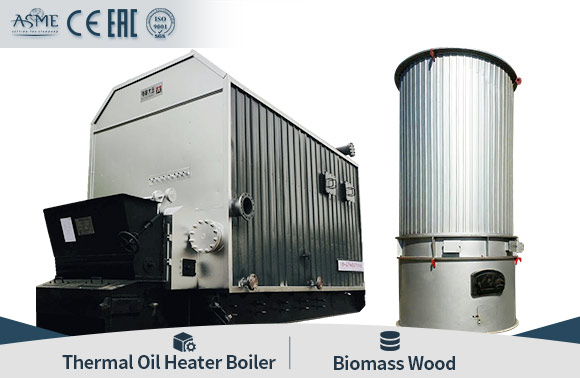

Related: Horizontal Thermal Oil Boiler

YYQW Series Coil Thermal Oil Heater.

Application of thermal oil boiler

1. Fuel applicable: Electric, Gas, Lpg, Diesel, Heavy Oil, Coal, Wood, Biomass, Agro Waste.

2. Application industry: Cement industry, Chemical/petrochemical industry, Polymer industry, Textile industry, Leather industry, Oil industry, Glue industry, Food processing industry, Metal industry, Tyre industry, Bitumen & Tar processing industry, Paper mills industry, Wood industry, Soap Detergent industry, Pharmaceutical industry, Paint Varnish industry Packing Packaging industry, Glass industry, Industrial Laundries

> How to Choose A Suitable Boiler

1. Basic Boiler Information For Your Project

Fuel options: Gas Lpg Diesel Heavy-oil Biogas Dual-fuel, Electricity, Coal, Charcoal, Wood, Biomass, Pellets, EFB Palm-kernel-shells, Rice-husk, Peanut-shells, Cashew-nuts-shells, Sunflower-seeds-shells, Bagasse, etc.

Thermal capacities options: 100kg-50000kg, 70kw-35000kw, 5hp/bhp-3000hp/bhp, (million-btu, pounds/lbs, liters,etc)

Heat medium options: saturated/superheated steam, hot water, thermal oil.

Structure options: Fire tube boiler, water tube boiler, water-tube fire-tube boiler

Layout options: Vertical boiler, Horizontal boiler.

Operating-mode options: Automatic, manual

Note: please feel free to send all requirements, we could help you better.

2. Calculating Running Cost

Specific consumption analysis report

Different types boiler running consumption comparison analysis report

(Note: Report is based on your local energy source price)

3. Boiler Accessories (essential or optional)

Control panel, Water treatment device, Economizer, Conderser, Heat recovery unit, Deaerator, Solid fuel burning combustions stoker (chain-grate, reciprocating-grate, travelling-grate, fixed-grate), Steam header, Pumps, Water level gauge/sensor, Pressure guage/sensor, Safety valves, etc.

Note: Any special request, please send all details.

Technical Parameter

| YY(Q)L Series Thermal Oil Boiler Technical Parameter | |||||||

| Model | Rated power(KW) | Rated pressure (Mpa) | Thermal oil temperature(℃) | Thermal efficiency(%) | Fuel comsumption | max transportation weigh(t) | |

| light diesel oil(kg/h) | natural gas(Nm³/h) | ||||||

| YY(Q)L-700Y(Q) | 700 | 0.8/1.0 | 250-320 | >96 | 61.3 | 73.6 | 3 |

| YY(Q)L-1400Y(Q) | 1400 | 0.8/1.0 | 250-320 | >96 | 122.6 | 147.1 | 4 |

| YY(Q)L-3000Y(Q) | 3000 | 0.8/1.0 | 250-320 | >96 | 249.2 | 296.4 | 10 |

| YY(Q)L-3500Y(Q) | 3500 | 0.8/1.0 | 250-320 | >96 | 305.6 | 366.8 | 10.2 |

| YY(Q)L4200Y(Q) | 4200 | 0.8/1.0 | 250-320 | >96 | 367.5 | 436.6 | 16.5 |

| YY(Q)L-5600Y(Q) | 5600 | 0.8/1.0 | 250-320 | >96 | 489.6 | 586.8 | 23.6 |

| YY(Q)L-7000Y(Q) | 7000 | 0.8/1.0 | 250-320 | >96 | 612.3 | 726.9 | 28 |

| Note: Parameter is for reference only, if any changes should follow the factory technical data. | |||||||

Our Supply Equipment List

Technical Design

Compace coil tube structure

Horizontal chamber combustion three coil structure, its body is composed of outer coil, middle coil, inner coil and rear coil.

Wet back sturcture

Unique design for heating surface in end of boiler, somke chamber wet back sturcuture, make lower heat loss, improve thermal efficiency 2%-3%.

External oil tank

The design of the external oil collecting tank prevents the slow flow of grease carbonization and avoids accidents.

100% safety runing & best insulation

Double layer 12cm aluminum silicate insulation. Sealed tightly to avoid air leaks. Over oil temperature/over smoke temperature/low flow alarm.Product Features

Intelligient & Fully Automatic

Offer world famous brand burner Weishaput/baltur/riello/hofat/Oilon, etc. Adopt mechanical-electrical integration control equipment and PLC touch screen electric control cabinet.

Energy-saving Efficient Gas/Oil Boiler

Thermal efficiency up to 99%, equipped with erengy-saving device Economizer, Condenser, Steam generator, Exhaust gas boiler. Fully absorb heat of flue gas and transfer to useful energy.

Steady Running & Easy Operation

Over oil temp/over steam temp alarm/low flow alarm, Compact coil tubes sturcture, heating oil efficiently. Sufficient arrangement, reducing thermal load of tubes surface to ensure safety.

Safety & 25+Years Lifespan

Double safety valve, double level gauges, double pressure gauge design: backup guarantee, safe and reliable; Smoke chamber ultrasonic testing, overpressure 40-50% water pressure test,ensure the boiler quality.

PRODUCTS LIST

More Products

Contact Supplier

Send Inquiry

Product capacity:

Product capacity: Working pressure:

Working pressure: Available fuel:

Available fuel: Available industries:

Available industries: