Introduction

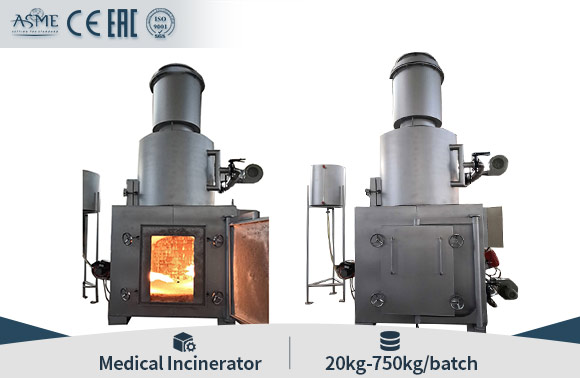

Solid Waste Garbage Management Incinerator

1. YDF series Incinerator is environmentally friendly equipment. Incinerators adopt high temperature heating technology. Harmful substances in waste are pyrolyzed at high temperatures and destroyed.

2. It is suitable for the harmless treatment of hospital medical waste, lab waste, domestic waste, pet cremation, animal carcasses waste, etc.

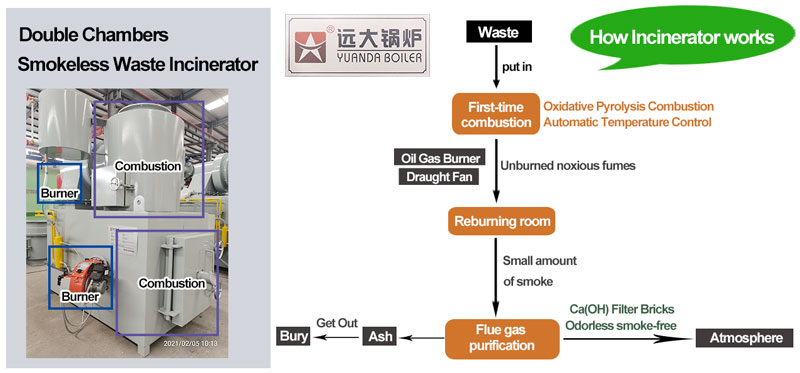

How Incinerator Works

YDF Incinerator Features

Our incinerator is provided with the currently most advanced incineration way, i.e., primary pyrolysis gasification + co-firing of surrounding wind +secondary incineration +burnout treatment.

1) The incinerator temperature reaches above the 1200°C continuously to ensure smokeless and tasteless and discharge up to standard.

2) Gasified incineration is used for burning syringe, paper waste, bandage, absorbent cotton and other medical wastes.

3) Gasified incineration, mixed incineration and burnout treatment ensures low emission standard of dust (lower than International standard).

4) Totally enclosed operation is suitable for treating infectious waste to avoid secondary pollution.

Kinds of Incinerators Showing

YDF Incinerator Cases

Yuanda Products Have Sold to 132 Countries & Regions, Global Sales & Services Worldwide

Incinerator Package & Delivery

We will pre-install the incinerator in factory, also do the commissioning work, then all parts detachable to small pieces for delivery.

Yuanda Incinerator Factory

1. Yuanda Company established since1956, mainly manufacture industrial boiler, incinerators.

2. Global sales with high quality products, with ISO CE ASME Certificates.

Technical Parameter

| Models | YDF-20 | YDF-30 | YDF-50 | YDF-100 | YDF-150 | YDF-300 | YDF-500 | |

| Processing Capacity (kg/batch) | 10-20 | 20-30 | 30-50 | 50-100 | 100-150 | 200-300 | 300-500 | |

| Working Hours Per Batch Cycle* (min) | 90-120 | |||||||

| Primary Chamber Volume (m3) | 0.2 | 0.38 | 0.5 | 1 | 1.5 | 2.4 | 3.5 | |

| Waste Feeding Gate Size (mm) | 380 x 480 | 480 x 600 | 620 x 800 | 700 x 900 | 760 x 960 | 900 x 1100 | 1080 x 1280 | |

| Temperature (℃) | Primary Chamber | 900 | ||||||

| Second Chamber | 1300 | |||||||

| Smoke Residence Time (s) | > 2 sec in second chamber | |||||||

| Applicable Waste Type | Hazard Medical Waste/Consumables, Plastic, Paper, Domestic Waste, Animal Corpse, Electronic Component | |||||||

| Primary Burner - Baltur Italy | BTL-6, 0.11kw | BTL-6, 0.11kw | BTL-10, 0.11kw | BTL-10, 0.11kw | BTL-10, 0.11kw | BTL-10, 0.11kw | BTL-14, 0.18kw | |

| Second Burner - Baltur Italy | BTL-10, 0.11kw | BTL-14, 0.18kw | BTL-14, 0.18kw | BTL-20, 0.18kw | BTL-20, 0.18kw | BTL-26, 0.25kw | BTL-35, 0.37kw | |

| Total Diesel** Consumption (litre/h) | 11-18 | 11-18 | 14-23 | 16-35 | 16-35 | 20-40 | 38-57 | |

| FD Fan Power (kw) | 0.37 | 0.37 | 0.55 | 0.75 | 0.75 | 0.75 | 0.75+0.75 | |

| Applicable Voltage | 380V 3Phase / 220V 1Phase | |||||||

| Outer Dimensions (m) | 1.6 x 1.3 x 2.65 | 1.45 x 0.9 x 2.6 | 1.8 x 1.2 x 3 | 1.86 x 1.4 x 3.2 | 2.1 x 1.5 x 3.5 | 2.25 x 1.6 x 3.8 | 3.0 x 2.0 x 4.8 | |

| Chimney Dimensions (mm) | φ280 x 6000 | φ280 x 6000 | φ300 x 9000 | φ330 x 9000 | φ380 x 9000 | φ400 x 9000 | φ460 x 9000 | |

| Weight (kg) | 2000 | 3000 | 5000 | 6800 | 8000 | 9600 | 15000 | |

| Manufacturing Standard | GB 18484-2020 (equals to EPA or EU standards) | |||||||

Waste Disposal

Incinerator Advantages

Devote To Use Easily

Easy operation, full automatically, one worker can operate it easily. Easy installation Well-debugged in factory. On-site Flange connection.

Firebrick

The interior adopts high temperature firebrick, which can withstand high temperature 1700ºC, the outer wall adopts thermal insulation brick to isolate heat.

High temperature pyrolysis technology

With the Italian baltur burner, the highest temperature can reach 1200 degrees Celsius, which can achieve the effect of sterilization and disinfection.

Smokeless & Odorless

Two-stage combustion technology, comply with national emission standards. Stable operation, low failure rate.How Incinerator works

1. Primary combustion chamber

It is Primary pyrolysis gasifying, Organic matters in the waste would be decomposed into combustible gas in pyrolysis gasifying method.

2. Second combustion chamber

The temperature of secondary combustion chamber should be controlled above 850℃, and the residency time more than 2s.

3. Mixture of combustion chamber

Turbulent combustion would remove black smoke and peculiar smell thoroughly. Dioxin and other toxic and harmful objects would be inhibited to produce from the source.

4. Smoke purification chamber

There is an gas absorbtion chamber, it can absorb the gas again.

5. Chimney

It can cool down the tempreture of waste gas.

PRODUCTS LIST

More Products

Contact Supplier

Send Inquiry

Product Brand:

Product Brand: Product Model:

Product Model: Available Fuel:

Available Fuel: Available Industries:

Available Industries: